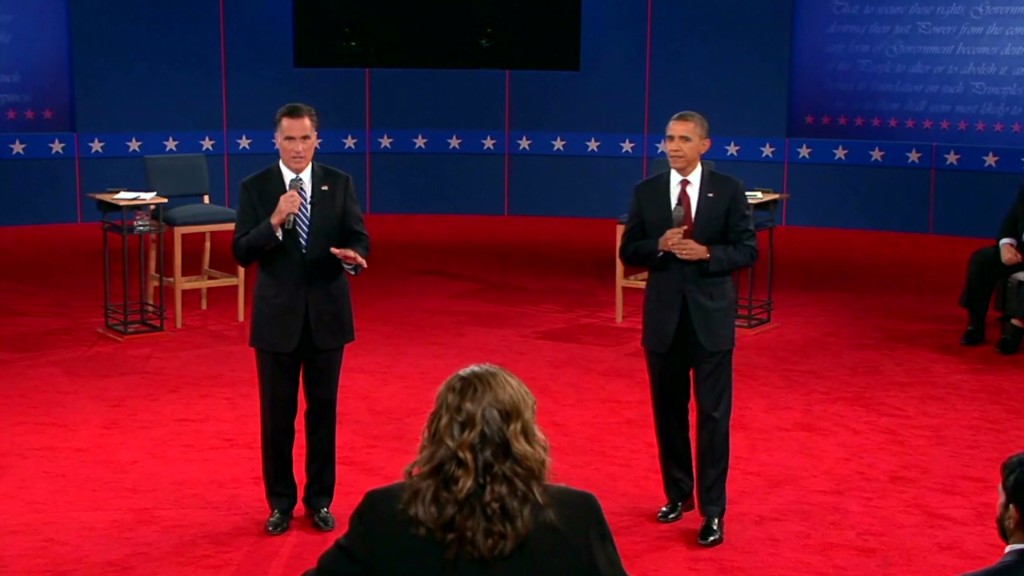

At the end of Tuesday night's presidential debate, CNN's Candy Crowley asked both candidates a question that has plagued Apple since the beginning of the year.

"IPad, the Macs, the iPhones, they are all manufactured in China, and one of the major reasons is labor is so much cheaper there," Crowley said. "How do you convince a great American company to bring that manufacturing back here?"

Mitt Romney said the solution is "very straightforward." The United States must pressure China to stop manipulating its currency, he said, and the federal government needs to "make America the most attractive place for entrepreneurs" by lowering taxes. He supports reducing the top corporate tax rate to 25%, down from its current 35%.

President Obama offered a starker answer: "Candy, there are some jobs that are not going to come back, because they're low-wage, low-skill jobs."

Speaking strictly for Apple, Obama's assessment is likely correct. Apple (AAPL) has said that it directly employs thousands of its own workers in China, and about 700,000 assembly workers at manufacturing contractors like Foxconn put together Apple products. It would be almost impossible to bring those jobs to the United States.

Foxconn -- China's largest private employer and the manufacturer of an estimated 40% half of the world's consumer electronic devices -- pays its assembly workers far less than American labor laws would allow. A typical salary is 2500 RMB (U.S. $400), or about $18 a day.

But pay isn't the biggest obstacle. Various economists have estimated how much an all-American labor force would add to the cost of an iPhone and come up with figures ranging from $65 to $100 per device.

Related story: Foxconn workers strike over iPhone 5 demands

The real stumbling block is speed. Unlike U.S. plants, Foxconn and other Chinese manufacturing operations house employees in dormitories and can send hundreds of thousands of workers to the assembly lines at a moment's notice. On the lines, workers are subjected to what most Americans would consider unbearably long hours and tough working conditions.

That system gives tech companies the efficiency needed to race products out the door. Plus, most of the component suppliers for Apple and other tech giants are also in China or other Asian countries. That geographic clustering gives companies the flexibility to change a product design at the last minute and still ship on time.

There's another catch, and it's one that politicians don't like to talk about: China has many more skilled engineers than the United States does.

Steve Jobs, Apple's late CEO, brought the issue up during an October 2010 meeting with President Obama. He called America's lackluster education system an obstacle for Apple, which needed 30,000 industrial engineers to support its on-site factory workers.

"You can't find that many in America to hire," Jobs told the president, according to his biographer, Walter Isaacson. "If you could educate these engineers, we could move more manufacturing plants here."

In a May interview with AllThingsD, Apple CEO Tim Cook said he agreed with Jobs' assessment.

"There has to be a fundamental change in the education system to bring back some of this [labor]," he said.

When asked if the day would ever come when an Apple product is made in the United States, he said: "I want there to be ... and you can bet that we'll use the whole of our influence on this."

That's a much more upbeat tone than the one his predecessor struck. During their meeting in 2010, Obama asked Jobs how to bring all the iPhone manufacturing jobs back to the United States, according to the New York Times.

"Those jobs aren't coming back," Jobs replied.