Andrew Rosa doesn't do back breaking work. His hands aren't swollen, blistered or greasy. He doesn't operate loud machines. He isn't in a labor union.

But Rosa is an American manufacturing worker. Specifically, he works in 3D print manufacturing -- a growing industrial sector that is redefining what a manufacturing job looks like today.

Its growth comes as President Trump is squarely focused on creating more manufacturing jobs by negotiating better trade deals. It also illustrates the successes and challenges of creating new manufacturing jobs amid a rapid pace of innovation that's replacing millions of industrial workers.

Rosa and his boss, Jim Allen, say trade deals aren't their problem. The big challenge in their view is the negative public perception among young people that manufacturing is dying.

"When I think of manufacturing, it's usually the old school train of thought," says Rosa, 27, an upstate New York native, who has worked at the factory for two years. "But this is very much manufacturing."

Related: My American job is moving to Mexico

Rosa oversees 160 computerized printers that quietly hum at the factory of Voodoo Manufacturing in Brooklyn, N.Y. Instead of laying ink on paper, the printers repetitively lay tiny layers of plastic filament on a glass plate to create a product. Rosa helps design and maps out the product that the printers make -- an extremely creative skill.

Voodoo's office feels more like a tech start up than a blue collar firm. The office has craft beer.

Entry-level employees earn $49,000. Rosa programs the printers to make just about anything -- from iPhone cases to prosthetic hands for amputees. He's even made a replica of the Wall Street bull.

Nike (NKE) called Voodoo on a recent Wednesday to make a pilot's helmet for a new display for Air Jordan shoes. It was done six days later -- a turnover time Allen argues couldn't be done from China.

Voodoo doesn't look like your traditional assembly line.

"We are a manufacturing company. But we're just doing it differently -- more of a 21st century way of doing it," says Allen. "It doesn't have to be some big sparky, smelting thing where you're producing big billets of steel. It could be quiet little machines that are just humming along, producing parts."

Voodoo began with four employees in 2015. The company has 17 employees today, 6 of whom oversee the printers. Within the next two years, Allen aims to add another 20 jobs. He credits a New York state tax credit for small businesses with helping the company grow.

Related: I send money home to Mexico to support my family

Nationwide, there are 20 firms with 3D print manufacturing plants, up from three in 2013, according to Wohlers Associates, an industry group.

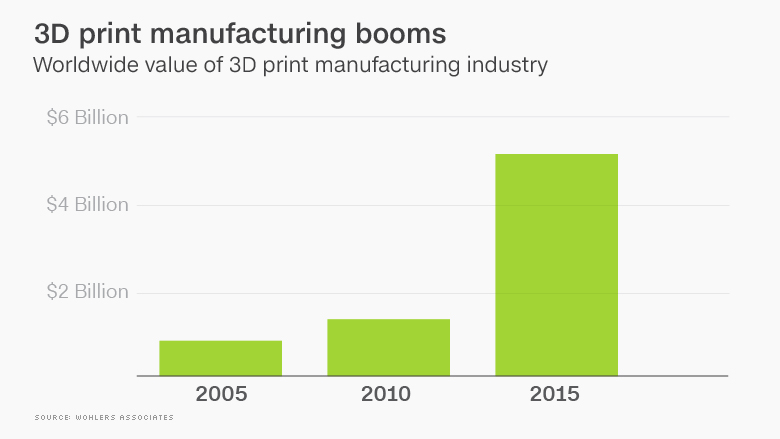

The industry was valued at $5.1 billion worldwide in 2015, up from less than $1 billion a decade ago, Wohlers Associates' reports.

Key to the Voodoo's success, Allen says, is something that's been in decline in many blue collar industries, especially manufacturing: job training and skills development.

Allen knows most colleges and high schools aren't teaching 3D print manufacturing. And he doesn't need PhDs or even college grads. He just needs workers willing to learn.

New hires shadow experienced employees and do manual labor first, such as cleaning the glass plates. But within a month they learn the company's software and how to program the printers -- more advanced work.

The idea is to have each employee capable of doing any task, making them more versatile.

"They're learning by doing," says Allen. "I want to give them a sense of ownership."

Trump says he plans to bring manufacturing jobs back to the United States by negotiating better trade deals. But he recently added one point to his jobs rhetoric.

"Workforce development and vocational training -- very important words," Trump said during his press conference with German Chancellor Angela Merkel on March 17.

Related: U.S. workers face higher risk of being replace by robots

Experts say training holds the key to adding manufacturing jobs in America. What's waning are the days of low-skill manufacturing: America doesn't make many t-shirts and toys anymore. Rising are advanced manufacturing jobs that require more critical thinking -- the 3D print manufacturer.

"3D print manufacturing has a lot of potential," says Susan Helper, an economics professor at Case Western Reserve University in Ohio. "If we have good job training, it's likely we could have more good paying jobs in 3D manufacturing."

Voodoo's willingness to train its workers is increasingly the exception, not the rule. Job training programs have been in decline due to costs, an aging workforce and a widening gap between the skills employers want and the skills employees have.

There were 21,000 apprenticeship programs in the U.S. last year, down from 26,000 in 2009 and 33,000 in 2001, according to Labor Department data.

Allen, the Voodoo director, is also wrangling with one of the toughest tasks in manufacturing: Using technology to create jobs instead of replace them. He says the technology of 3D printing complements humans.

Automation "is going to be a net job creator," Allen argues. "We're printing different products every day. ... It's something that's going to require critical thinking skills that a person has and a robot doesn't."

Related: Rise of the machines: Fear robots, not China or Mexico

Of course, manufacturing overall has a different story.

Several studies show automation was the overwhelming reason why America has lost roughly 5 million manufacturing jobs since 2000. One study by Ball State University concluded that 87% of the factory job losses between 2000 and 2010 were due to more efficient practices, especially better technology.

The rub is that automation also creates jobs -- just ones that require more skills than the ones lost. And often the worker who loses his or her job to automation isn't the one who gets the new job, creating winners and losers.

Displaced workers "would have to totally re-skill to get a different type of job," says Cathy Barrera, chief economic adviser at ZipRecruiter, a job search site. "We can have job growth that is sufficient to counteract the decline. But it could possibly be that none of [the new jobs] are in manufacturing."