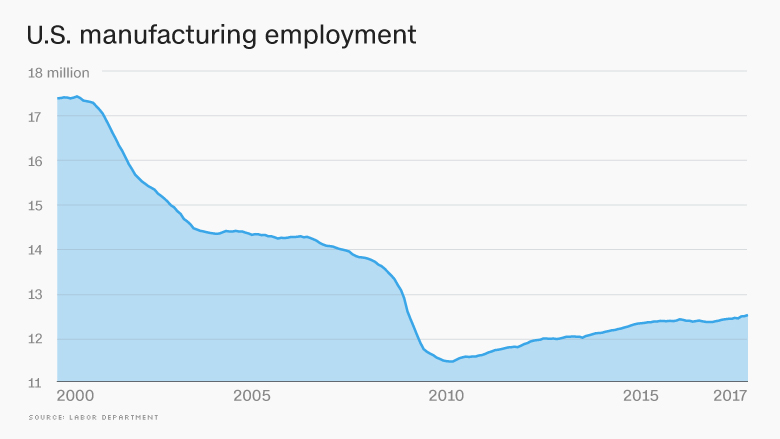

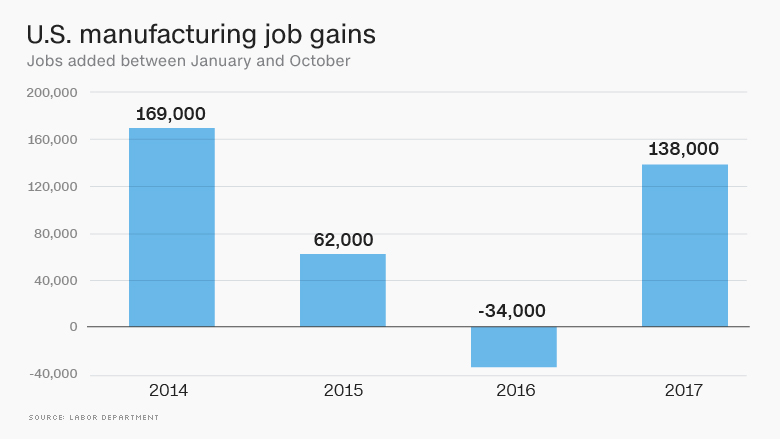

In President Trump's first year in office, American factories are adding jobs at the fastest pace since 2014.

But that's not just because of Trump. Lots of factors have contributed to the comeback in manufacturing.

The president gets credit for boosting overall business optimism and consumer confidence, although both had been rising for years before he took office. But a weaker dollar, which makes it easier for American companies to sell products abroad, and an ever-stronger global economy have also helped factories grow.

More good news came Friday: The manufacturing industry expanded in November for the 15th month in a row, according to the monthly ISM index. It's been growing almost nonstop since a brief five-month recession that began in late 2015.

Related: NAFTA talks are in trouble

And the United States has added 138,000 manufacturing jobs so far this year, far better than the 34,000 factory jobs lost over the same period last year. Last year's losses reinforced President Trump's portrayal of manufacturing in a long decline.

"One by one, the factories shuttered and left our shores, with not even a thought about the millions upon millions of American workers left behind," he said in his inaugural address in January.

Despite that narrative of lost jobs, some measures show the industry is thriving. For example, what's known as the industry's total real output, the value of all the goods it produces, has been hovering near an all-time high for three years.

Trump campaigned heavily on bringing manufacturing jobs back to the United States, particularly by renegotiating America's trade deals, such as NAFTA, the pact with Canada and Mexico. All three countries say NAFTA negotiations are not going well, despite some progress on peripheral issues.

Regardless of trade policy, though, manufacturing has rebounded for a variety of reasons, both domestic and global.

Related: U.S. wins tuna trade battle against Mexico

Manufacturing has benefited this year from a weaker U.S. dollar. The industry depends heavily on exporting its products -- from pipes to pickup trucks. When the dollar's value is high, as it was in 2015, when manufacturing was in a recession, U.S. exports are more expensive and less attractive to foreign buyers.

The dollar is down about 9% compared with the world's most traded currencies this year, according to the ICE dollar index. At the same time, the global economy is on pace to post its best year of growth since 2011, according to the IMF.

Put those two factors together, and it's not surprising that U.S. exports were up 8% in the first half of this year compared with the same period in 2016.

Another factor: The U.S. economy is performing well. Unemployment is 4.1%, its lowest since 2000. The economy has added jobs for 85 consecutive months, the longest streak in recorded U.S. history. A healthy economy increases demand for manufactured goods in America, from cars to solar panels.

Companies have been hiring in particular for manufacturing jobs in metals and electronic products. Those sectors have added 32,000 jobs and 13,000 jobs respectively.

Related: Mexico is surviving Year 1 of Trump

Germán Curá plans to bring 600 manufacturing jobs in December to Bay City, Texas, where his European firm, Tenaris, is opening a $1.8 billion steel pipe plant. The rise of the U.S. shale industry largely drove the company's decision to open the plant, but Curá argues that the ability to use advanced technology to create jobs also played a role.

Along with market size and enforcement of trade laws, "I think manufacturing in the States is coming back because companies have understood that with the appropriate technology with automation ... in the end it's translated in our ability to look at manufacturing as a sustainable, feasible activity," he says.

That sentiment may mark a shift in manufacturing, which has long been considered a victim of automation. One study from Ball State University estimates that 87% of the manufacturing jobs lost between 2000 and 2010 were attributed to automation and improved efficiency.

Curá says the typical employee at Tenaris, which also has operations in Canada and Mexico, has changed from "a person pushing a pipe to a person operating a robot."

In surveys, manufacturers across the United States say they can't find workers with the right skills, causing some positions to go unfilled. The Trump administration plans to invest more federal dollars in apprenticeship programs.

Curá adds that manufacturers don't have a choice. They need to prepare workers for the factory jobs of the future. Tenaris has an in-house job training program for new hires.

"Our job as a manufacturing industry overall is to embrace something that's unavoidable and retrain workers," Curá says.