For all but the most elite athletes, buying athletic shoes can be hit or miss: Go to the store, find something you like, and try it on. If it doesn't feel quite right, too bad. Try another shoe.

Adidas sees a future where motion capture tech, data analysis software, and 3D printing come together in the store to create a pair of kicks tailored to your exact needs. One foot slightly smaller than the other? No problem. You overpronate? Don't worry about it. Technology will provide the perfect shoe.

All of the big shoe companies are racing toward that goal. Adidas offered a glimpse of how that might happen when it brought its pop-up Speedfactory Lab Experience to Brooklyn, New York.

The pop-up replicated some of the work Adidas (ADDDF) does at its automated Speedfactory laboratories in Atlanta and Ansbach, Germany. The R&D centers are a proving ground for tricks and technologies Adidas can use to quickly and efficiently produce customized shoes that fit perfectly.

My visit to the Speedfactory Lab Experience started with designers scanning my feet to determine their exact length, width, and positioning. Cameras recorded my stride, speed, and gait as I ran on a treadmill.

All of this data appeared on two screens in front me. I discovered that my left foot is slightly longer and wider than my right, and I am what physiologists call a "neutral runner." That means my feet roll slightly inward after making contact with the ground, evenly distributing my weight while helping absorb the impact.

Knowing such things is essential to selecting the right running shoe. But Adidas wants to take things one step further and use that info to create your perfect shoe in almost not time at all.

Adidas can't do that yet, but it's getting there. Zachary Coonrod, senior designer on the futures team at Adidas, said its Speedfactory labs are getting speedier. "We're three times faster in terms of bringing product from idea to market," he said.

Good, but not good enough, said Sucharita Kodali, a retail analyst at Forrester Research.

"The vision of on-demand fast shoes is a great one, but what [Adidas] can actually do is only create a few items on demand quickly," she said. "That's not impressive. If they could create any custom item quickly, that would be a game changer, but that's not what they do -- yet."

Related: Adidas is still crushing Nike and Under Armour in America

The Speedfactory uses 3D printing, automated manufacturing, and other technology to produce limited edition shoes. So far that's meant developing sneakers tailored to the needs of runners in specific locales. The project started in 2016 with a shoe just for Germany. The company has designed kicks for runners in London, Paris, and New York with its AM4 (Adidas Made For) line. Shoes for runners in Tokyo and Shanghai are in the works.

You might wonder why runners in different cities need different shoes. Well, Adidas discovered that runners in the Big Apple tend to make sharp turns at higher speeds than folks in London. Subtle tweaks to the upper --the top portion of the shoe -- on the AM4NYC help improve stability and agility in such circumstances.

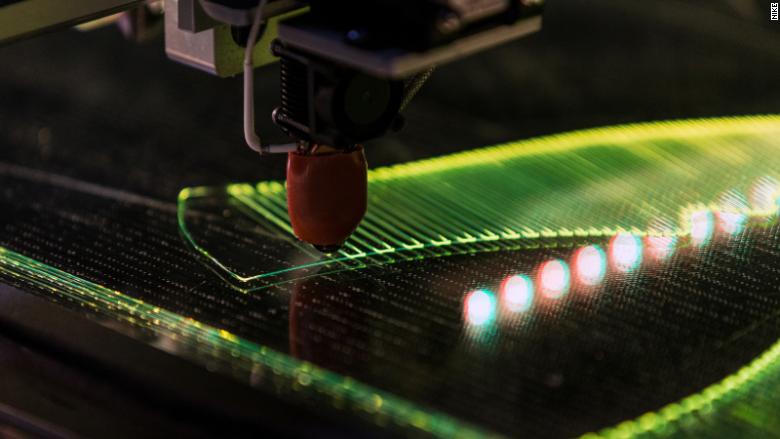

To further customize shoes, Adidas is working with Silicon Valley startup Carbon to tailor midsoles -- arguably the most important part of the shoe. Carbon uses a 3D manufacturing process called Digital Light Synthesis to produce stiff elastomer midsoles that could outperform some of the best foams and gels. Ultimately, adidas plans to incorporate Carbon's manufacturing process into the Speedfactory to expand production and offer more personalized products.

Related: Clash of the Titans: Adidas and Nike continue to battle it out

Adidas unveiled its first product with a Carbon insole in 2017, the Futurecraft 4D. A limited run of the shoes was released to the public earlier this year -- at $300 a pair -- and it sold out instantly. The company plans to release more than 100,000 pairs by the end of this year. That's a lot of shoes, but nothing compared to the 400 million pairs of shoes it cranked out last year.

Given that kind of scale, you can see why Adidas wants the ability to produce custom shoes in a hurry. It isn't alone in chasing this goal. Brooks Running has teamed up with HP to create FitStation, which uses 3D printing to make insoles and polyurethane injection-molded midsoles for customized shoes. Nike (NKE) started testing its own 3D-printed material, Flyprint, in April. The material allows Nike to tailor a shoe's upper to a runner's foot shape, gait and needs.

None of this comes cheaply, though. The Nike Zoom Vaporfly Elite Flyprint sold for $600, and Nike has so far released only a small number of them. The company has not said whether it will make the shoe more widely available in the future. That's an essential question, because cost and availability remain the biggest hurdle between you and a pair of bespoke shoes.

"Brands can make custom products now, but the shoes themselves are far too expensive to be commercial," said Matt Powell, a senior industry analyst for NPD. "It does not matter who is first [to make them] -- what matters is who is first commercially."

So far, only the world's best athletes enjoy this level of customization. But if Adidas and its competitors can get the technology to work, you may one day walk out of a store with a pair of shoes that fit like a glove.