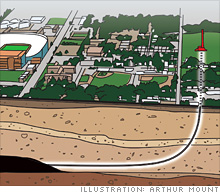

How they did it: Drilling a horizontal well

(Fortune Small Business) -- Directional drilling was developed in 1929, but horizontal oil drilling became cost-effective and technically feasible only about five years ago.

Drillers extract natural gas in shale formations from West Texas all the way up into the Appalachians, but these formations cover entire counties and can be 200 or 300 feet thick. Mark Herndon's target in the Lower Skinner Sandstone in Stillwater, Okla., was at best 15 to 20 feet thick and nearly a mile underground.

Steering blind, he needed to guide the drillers in a gradual 90-degree arc. A 30-foot section of steel drilling pipe doesn't bend. But if you string together a thousand feet of that pipe, it can be curved horizontally. The drillers use a half-million-dollar down-hole mud motor - it looks like a regular pipe but has an adjustable housing that can be canted up to four degrees. At one end is a drill bit, at the other an articulated drive shaft and a rotor. It is powered by high-pressure drilling mud flowing from the surface rig.

Guided by the geologist, the drillers start "building the curve" at a rate of nine degrees per hundred feet, until they reach a well inclination of 90 degrees from vertical - the point at which they hope to find oil. ![]()

-

The Cheesecake Factory created smaller portions to survive the downturn. Play

-

A breeder of award-winning marijuana seeds is following the money and heading to the U.S. More

-

Most small businesses die within five years, but Amish businesses have a survival rate north of 90%. More

-

The 10 most popular franchise brands over the past decade -- and their failure rates. More

-

These firms are the last left in America making iconic products now in their twilight. More