|

Two doomed auto plants named the best

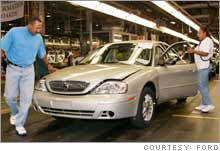

Study shows Ford Atlanta plant slated for closure this year takes fewest hours to build car; No. 2 in rankings is GM plant slated for closure in '08.

NEW YORK (CNNMoney.com) - The two most efficient auto assembly plants in North America are a Ford plant in Atlanta and a General Motors plant in Ontario - and both of them are going to close. Rankings of auto plant efficiency were released Thursday by Harbour Consulting, a widely respected Michigan research firm used by the automakers to judge their plants' productivity.

The good news for GM (Research), Ford (Research) and DaimlerChrysler's (Research) Chrysler Group is that all three made progress in 2005, narrowing the efficiency gap with North American plants operated by Toyota (Research), Honda (Research) and Nissan (Research). But the bad news is that some of Ford's and GM's most productive car assembly lines are the ones on the chopping block as the companies aim to trim excess capacity. Ford spokeswoman Anne Marie Gattari said one of the reasons the Atlanta plant was so productive was that the Taurus sedans built there has not been changed in many years. She said they're essentially built for sale to rental car companies, making assembly more simplified than at plants building newer vehicles for the consumer market. The Atlanta plant, which employs about 2,000 people, took an average of 15.37 work hours to build each vehicle, while GM's Oshawa No. 2 assembly plant in Ontario, took an average of 16.08 hours to build the Allure, Grand Prix and Lacrosse. It is slated to be idled after GM stops making those models in 2008. Gattari said Ford never blamed the Atlanta plant's productivity for its plans to idle the plant in the second half of 2006. "There are many business factors that go into deciding which plants will be idled and which plants will not be," she said, citing the life cycle of the vehicle being built there, the logistics costs and need for additional investment going forward. "We are very pleased with this plant's performance over the years." Dan Flores, a spokesperson for GM, echoed Gattari's comments that the plans to shut plants was not a comment on the work forces at the affected facilities. "The announcement we made last fall with regards to the restructuring was very difficult. We obviously do have plants that perform well in the Harbour report being impacted. We faced a very difficult fact that we have too much manufacturing capacity compared to what the market wants. There are a lot of factors that go into the decision; productivity is only one of them." GM places five

GM had five of its plants in Harbour's ranking of 10 most efficient. But one of those, the Spring Hill #1 plant in Tennessee that builds Saturn Ions, is also on the list of plants that will close. The plant, scheduled to shut by the end of 2006, was No. 10 on the list of most efficient, and it also had the distinction of being the most efficient sub-compact car plant. Flores and Gattari both made the distinction that their companies are idling the plants, and not closing the door to future investment and future operation. GM is studying making further investment at the Spring Hill plant, Flores said. Another one of GM's most efficient facilities, the Oshawa No. 1 assembly plant, ranked No. 7 by Harbour, will lose one of its three shifts by the end of this year. Both GM and Ford announced plans to close about a dozen plants and facilities apiece in the coming years in order to trim capacity. The Harbour report shows a need for both companies to make those cuts, as it put GM production at 90 percent of capacity and Ford operating at only 79 percent of capacity. Toyota's North American plants operated at 106 percent of capacity, while Nissan was at 95 percent of capacity. Honda plants here were operating at 91 percent of capacity. Nissan's North American plants were judged the most efficient overall, although two of its Mexican plants were not included in the ranking. Harbour estimated Nissan required 18.93 work hours per vehicle for its overall production, although that was 3.5 percent longer than its 2004 estimate. Toyota and Honda were almost tied for next most efficient, with Toyota's North American plants taking 21.33 hours and Honda taking 21.43 hours. But both those companies also saw the average time it took to build cars increase over the previous year. "You need to look at types of vehicles they're building in the new plants," said Harbour's Greg Gardner. "They tend to be larger vehicles which are a little more complex." GM improved its efficiency by 2.3 percent in 2005. It took an average of 22.42 hours per vehicle. Ford and Chrysler were essentially tied, with Chrysler improving efficiency by 5.7 percent to 23.73 hours, while Ford improved by 2.9 percent to 23.77 hours. ------- For a look at GM's plant closing plans, click here. For a look at Ford's plant closing plans, click here.

For more news on autos and automakers, click here. |

|